Description

Compressed non-asbestos sheet gasket material produced from a combination of aramid fiber, inorganic fillers and bonded with styrene-butadiene rubber (SBR). It is a high quality sheet for general service with excellent sealing properties. Even if it compressed this sheet stays stable.

Applications

The 3R 870 has numerous applications in the process industries handling media like:

– Mild acids and alkali

– General chemicals

– Industrial gases

– Brine

– Water

– Neutral solutions

– Air

– Saturated steam

Specifications

| Color | Off White |

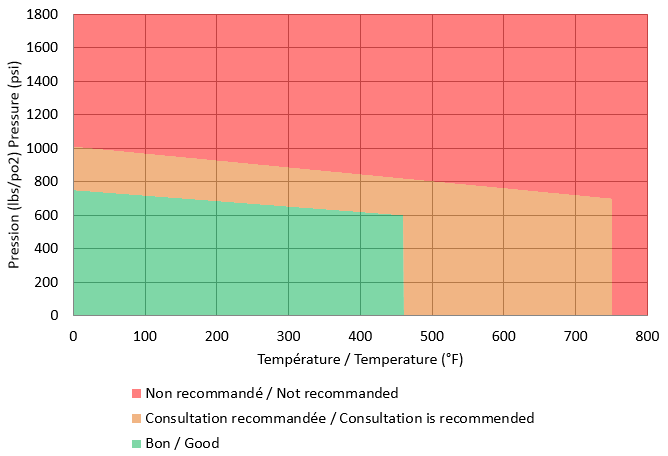

| Temperature | Continuous: 270°C (518°F), Short period: 380°C (715°F) |

| Pressure | Continuous: 725 psi (50 bar), Short period: 1015 psi (70 bar) |

| Thickness | 1/64" to 1/8" |

| Density | 112 lb/ft³ (1.80 g/cm³) |

| Compressibility (ASTM F36) | 7-17% |

| Recovery (ASTM F36) | 50% min. |

| Ignition Loss (ASTM F495) | 27% max. |

| Thickness increase after 5 hour immersion (ASTM F146) ASTM IRM 903 @ 300°F (150°C) | 40% max. |

| hickness increase after 5 hour immersion (ASTM F146) ASTM Fuel B @ 77°F (25°C) | 20% max. |

| Weight increase after 5 hour immersion (ASTM F146) ASTM IRM 903 @ 300°F (150°C) | 30% max. |

| Weight increase after 5 hour immersion (ASTM F146) ASTM Fuel B @ 77°F (25°C) | 30% max. |

| Torque retention (DIN 52913) | 32 MPa |

N.B. The information presented may differ from practice. We recommend conducting tests according to the conditions of use. We accept no responsibility for results obtained by the application of this information or the safety and suitability of our products. The data is subject to certain variations without notice.