Molding

Molding is a process that enables the production of parts with complex geometries that are difficult to achieve through machining or assembly. It allows for the integration of inserts, reinforcements, and other technical elements while minimizing raw material waste and ensuring consistent reproducibility.

At Industries 3R, we primarily produce molded parts using refractory concrete for its exceptional high-temperature resistance (such as aluminum smelter furnace plugs), polyurethane for its flexibility and abrasion resistance (like conveyor buckets used in mining), and silicone, which offers good heat resistance while maintaining flexibility (molded sealing gaskets).

Filter posts

Silicone molding

Silicone molding allows for the production of complex parts that offer good flexibility and temperature resistance (± 500°F). Other materials can be incorporated to obtain specific characteristics.

Polyurethane molding

Polyurethane molding allows for the manufacture of complex parts. Polyurethane stands out for its mechanical strength, particularly against abrasion, and offers a wide range of hardness levels.

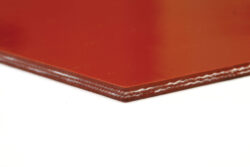

Laminated fabrics

Laminating fabrics using silicone allows the specific properties of each (mechanical strength, abrasion resistance, heat reflection, etc.) to be combined in order to obtain products that are better suited to certain specific needs.

Refractory molding

Refractory concrete castings have very high temperature resistance. The casting process makes it possible to obtain shapes that are difficult to achieve through machining, while also offering the possibility of adding hardware elements, thus facilitating assembly and use.