NORPLY™

Download

Description

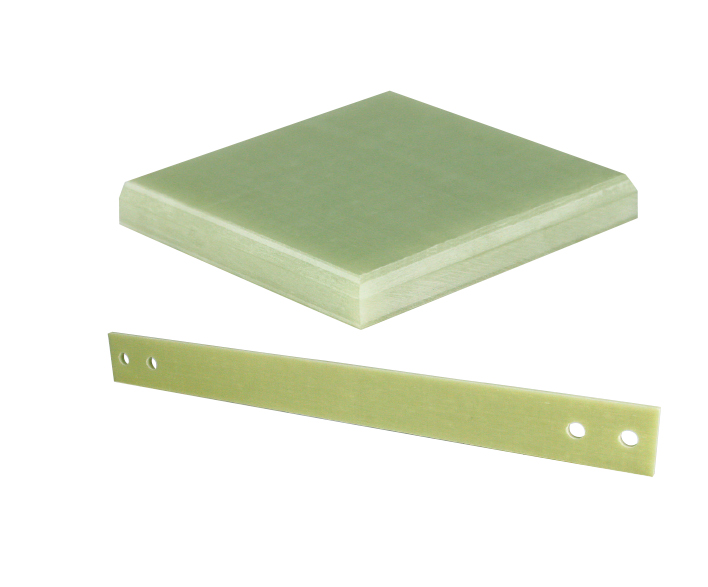

NORPLY™ is a cured epoxy composite material based on a unique non-woven, parallel filament construction. This type of construction minimizes filament stress abrasion that can shorten fatigue life in conventional reinforced plastics. NORPLY™ uses type E continuous filament fiberglass. It is supplied as cured flat panels or cut to size shapes.

Features and benefits:

- High impact strength

- High strength-to-weight performance

- Low notch sensitivity

- Resistant to cleaning fluids and solvents

- Weight reduction

- Chemical and corrosion resistance

- Excellent fatigue life and high strain capability

- Less downtime in harsh environnements

- Greater capacity to store energy thant 1060 spring steel

NORPLY™ is available in unidirectional, cross-ply or isotropic fiber orientation, each offering a different balance of physical propterties.

Applications

NORPLY™ can bu used in many applications including :

- Vibratory springs

- Dock shelter staves

- Shocks and struts

- Insulation spacers

- Insulated rail joints

- Flexible couplings

- Furniture springs

Specifications

| Dissipation factor Conditioned @ R.H. | 50% |

| Dissipation factor Test temperature | 23°C |

| Dissipation factor Frequency 1KC | 0.006 |

| Dielectric constant Conditioned @ R.H. | 50% |

| Dielectric constant Test temperature | 23°C |

| Dielectric constant Frequency 1 KC | 5.2 |

| Volume resistivity (Ohms-cm) Conditioned @ R.H. | 50% |

| Volume resistivity (Ohms-cm) Test temperature | 23°C |

| Volume resistivity (Ohms-cm) Frequency 60 Hz (109 V.D.C) | 4.9 X 1017 |

| Insulation resistance (Ohms) Conditioned @ R.H. | 50% |

| Insulation resistance (Ohms) Test temperature | 23°C |

| Insulation resistance (Ohms) Frequency (109 V.D.C.) | 6.2 X 1011 |

| Dielectric strength Conditioned @ R.H. | 50% |

| Dielectric strength Test temperature | 23°C |

| Dielectric strength Frequency (Volts/Mil) | 620 |

| Arc Resistance Conditioned @ R.H. | 90% |

| Arc Resistance Test temperature | 23°C |

| Arc Resistance Time in seconds Across filaments | 80 |

| Arc Resistance Time in seconds With filaments | 20 |

| Unidirectional Flexural strength (PSI x 103) (ASTM D-790) -50°C (-60°F) | 192 (1320 MPa) |

| Unidirectional Flexural strength (PSI x 103) (ASTM D-790) 21°C (70°F) | 167 (1150 MPa) |

| Unidirectional Flexural strength (PSI x 103) (ASTM D-790) 71°C (160°F) | 135 (930 MPa) |

| Unidirectional Flexural strength (PSI x 103) (ASTM D-790) 121°C (250°F) | 90 (620 MPa) |

| Crossply Flexural strength (PSI x 103) (ASTM D-790) -50°C (-60°F) | 125 (865 MPa) |

| Crossply Flexural strength (PSI x 103) (ASTM D-790) 21°C (70°F) | 110 (760 MPa) |

| Crossply Flexural strength (PSI x 103) (ASTM D-790) 71°C (160°F) | 87 (600 MPa) |

| Crossply Flexural strength (PSI x 103) (ASTM D-790) 121°C (250°F) | 67 (460 MPa) |

| Isotropic Flexural strength (PSI x 103) (ASTM D-790) -50°C (-60°F) | 100 (690 MPa) |

| Isotropic Flexural strength (PSI x 103) (ASTM D-790) 21°C (70°F) | 76 (525 MPa) |

| Isotropic Flexural strength (PSI x 103) (ASTM D-790) 71°C (160°F) | 76 (600 MPa) |

| Isotropic Flexural strength (PSI x 103) (ASTM D-790) 121°C (250°F) | 98 (435 MPa) |

| Unidirectional Flexural modulus (PSI x 103) (ASTM D-790) -50°C (-60°F) | 5.7 (39.3 GPa) |

| Unidirectional Flexural modulus (PSI x 103) (ASTM D-790) 21°C (70°F) | 5.6 (38.6 Gpa) |

| Unidirectional Flexural modulus (PSI x 103) (ASTM D-790) 71°C (160°F) | 5.2 (35.9 Gpa) |

| Unidirectional Flexural modulus (PSI x 103) (ASTM D-790) 121°C (250°F) | 5.0 (34.5 Gpa) |

| Crossply Flexural modulus (PSI x 103) (ASTM D-790) -50°C (-60°F) | 3.6 (24.8 GPa) |

| Crossply Flexural modulus (PSI x 103) (ASTM D-790) 21°C (70°F) | 3.5 (24.1 GPa) |

| Crossply Flexural modulus (PSI x 103) (ASTM D-790) 71°C (160°F) | 3.3 (22.8 GPa) |

| Crossply Flexural modulus (PSI x 103) (ASTM D-790) 121°C (250°F) | 2.9 (20.0 GPa) |

| Isotropic Flexural modulus (PSI x 103) (ASTM D-790) -50°C (-60°F) | 2.9 (20.0 GPa) |

| Isotropic Flexural modulus (PSI x 103) (ASTM D-790) 21°C (70°F) | 2.9 (20.0 GPa) |

| Isotropic Flexural modulus (PSI x 103) (ASTM D-790) 71°C (160°F) | 2.9 (20.0 GPa) |

| Isotropic Flexural modulus (PSI x 103) (ASTM D-790) 121°C (250°F) | 2.3 (15.9 GPa) |

| Unidirectional Tensile strength (PSI x 103) (ASTM D-638) -50°C (-60°F) | 150 (1035 MPa) |

| Unidirectional Tensile strength (PSI x 103) (ASTM D-638) 21°C (70°F) | 140 (965 Mpa) |

| Unidirectional Tensile strength (PSI x 103) (ASTM D-638) 71°C (160°F) | 130 (895 Mpa) |

| Unidirectional Tensile strength (PSI x 103) (ASTM D-638) 121°C (250°F) | 108 (745 Mpa) |

| Crossply Tensile strength (PSI x 103) (ASTM D-638) -50°C (-60°F) | 85 (580 Mpa) |

| Crossply Tensile strength (PSI x 103) (ASTM D-638) 21°C (70°F) | 70 (480 Mpa) |

| Crossply Tensile strength (PSI x 103) (ASTM D-638) 71°C (160°F) | 65 (450 Mpa) |

| Crossply Tensile strength (PSI x 103) (ASTM D-638) 121°C (250°F) | 61 (420 Mpa) |

| Isotropic Tensile strength (PSI x 103) (ASTM D-638) -50°C (-60°F) | 58 (400 Mpa) |

| Isotropic Tensile strength (PSI x 103) (ASTM D-638) 21°C (70°F) | 48 (330 Mpa) |

| Isotropic Tensile strength (PSI x 103) (ASTM D-638) 71°C (160°F) | 45 (310 Mpa) |

| Isotropic Tensile strength (PSI x 103) (ASTM D-638) 121°C (250°F) | 36 (250 Mpa) |

| Unidirectional Tensile modulus (PSI x 106) (ASTM D-638) 21°C (70°F) | 5.7 (39.3 GPa) |

| Unidirectional Tensile modulus (PSI x 106) (ASTM D-638) 71°C (160°F) | 5.6 (38.6 Gpa) |

| Unidirectional Tensile modulus (PSI x 106) (ASTM D-638) 121°C (250°F) | 5.2 (35.8 Gpa) |

| Crossply Tensile modulus (PSI x 106) (ASTM D-638) 21°C (70°F) | 3.4 (23.4 Gpa) |

| Crossply Tensile modulus (PSI x 106) (ASTM D-638) 71°C (160°F) | 3.4 (23.4 Gpa) |

| Crossply Tensile modulus (PSI x 106) (ASTM D-638) 121°C (250°F) | 2.7 (18.6 Gpa) |

| Isotropic Tensile modulus (PSI x 106) (ASTM D-638) 21°C (70°F) | 2.5 (17.2 Gpa) |

| Isotropic Tensile modulus (PSI x 106) (ASTM D-638) 71°C (160°F) | 2.4 (16.5 Gpa) |

| Isotropic Tensile modulus (PSI x 106) (ASTM D-638) 121°C (250°F) | 1.8 (12.4 Gpa) |

| Unidirectional Compressive strength (PSI x 103) (ASTM D-3410) -50°C (-60°F) | 160 (1100 Mpa) |

| Unidirectional Compressive strength (PSI x 103) (ASTM D-3410) 21°C (70°F) | 128 (880 Mpa) |

| Unidirectional Compressive strength (PSI x 103) (ASTM D-3410) 121°C (250°F) | 84 (580 MPa) |

| Unidirectional Compressive strength (PSI x 103) (ASTM D-3410) 71°C (160°F) | 114 (785 Mpa) |

| Crossply Compressive strength (PSI x 103) (ASTM D-3410) -50°C (-60°F) | 110 (760 MPa) |

| Crossply Compressive strength (PSI x 103) (ASTM D-3410) 21°C (70°F) | 100 (690 MPa) |

| Crossply Compressive strength (PSI x 103) (ASTM D-3410) 71°C (160°F) | 88 (605 MPa) |

| Crossply Compressive strength (PSI x 103) (ASTM D-3410) 121°C (250°F) | 63 (435 MPa) |

| Isotropic Compressive strength (PSI x 103) (ASTM D-3410) -50°C (-60°F) | 87 (605 MPa) |

| Isotropic Compressive strength (PSI x 103) (ASTM D-3410) 21°C (70°F) | 75 (520 MPa) |

| Isotropic Compressive strength (PSI x 103) (ASTM D-3410) 71°C (160°F) | 61 (420 MPa) |

| Isotropic Compressive strength (PSI x 103) (ASTM D-3410) 121°C (250°F) | 39 (270 MPa) |

| Weight (lb/yd²) (kg/m²) | 0.85 (046) Unidirectional |

| Resin Content (% by weight) | 36 +/- 3% |

| Specific gravity (cured average) | 1.85 |

| Barcol hardness | 70 |

| Wet strength retention (2 hours boil) | 85% |

N.B. The information presented may differ from practice. We recommend conducting tests according to the conditions of use. We accept no responsibility for results obtained by the application of this information or the safety and suitability of our products. The data is subject to certain variations without notice.